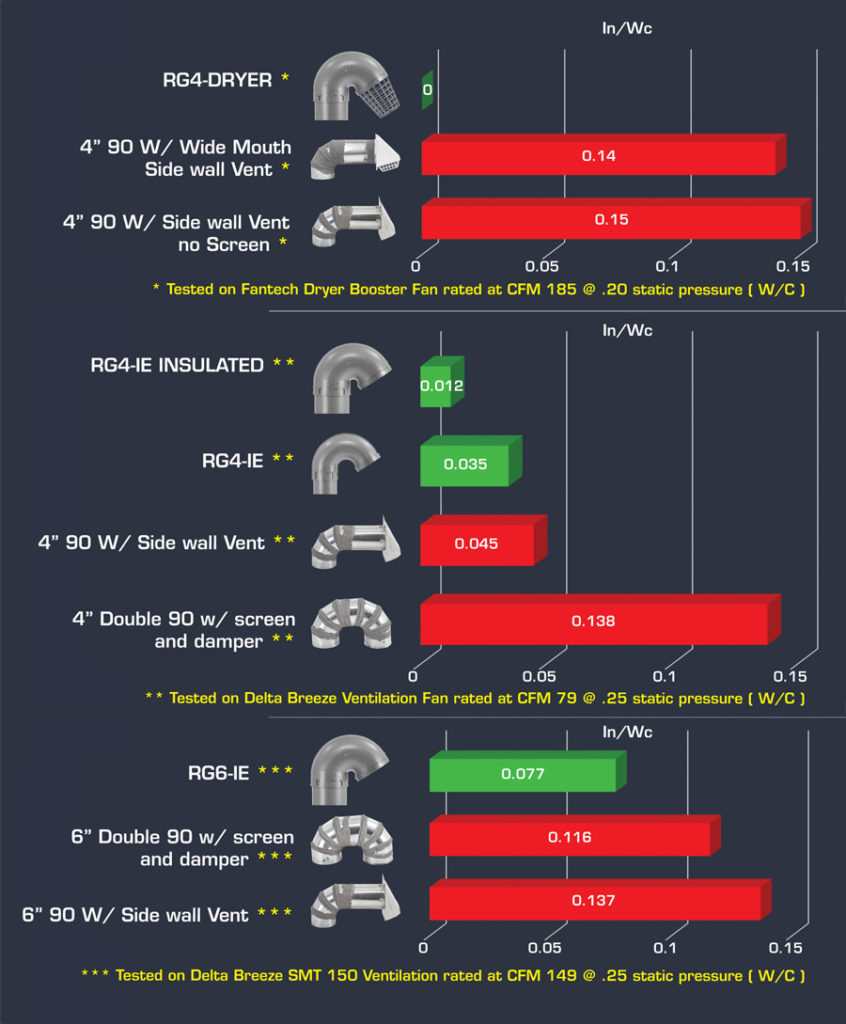

Compare RoofGoose with Other Vents

Why is RoofGoose Vent Better?

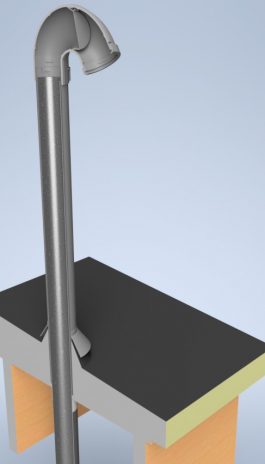

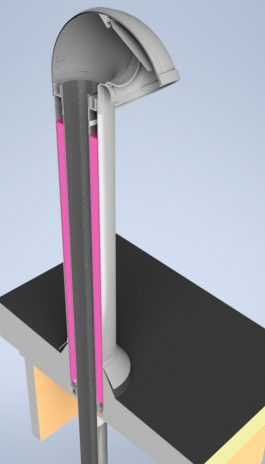

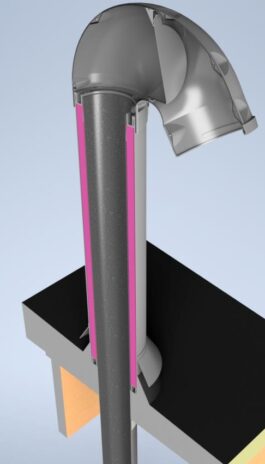

Roofgoosevent is better because it was designed to solve every issue above the roof associated with vertical small diameter flat roof vent and intake terminations. It was designed by a high-volume multifamily HVAC subcontractor who has seen numerous field designed and fabricated assemblies all with their own unique deficiencies as well as the water infiltration concerns that they all share. It’s a packaged solution to a neglected aspect of HVAC terminations. From the duct riser clamp to ensure a plumb riser to the insulation provided on selected models the design and included components are all thought out.

The static pressure added by any Roofgoose model with backdraft damper and screen is the same or substantially less than any field assembled gooseneck without a backdraft damper. Any field installer with a 5/16″ Impact can install a complete assembly in less than 5 minutes and in most cases less if the underlying duct is installed at an earlier time. The Roofgoose sleeve instantly protects the underlying galvanized duct and gives the roofer a superior UV resistant plastic assembly to flash to extending the life span of the roof penetration. The included counter flashing shields and shades the underlying roof flashing again extending its useful life. The Roofgoose Vent can be installed regardless of the temperature or the weather. Owners and maintenance staff can service the termination and connected equipment easily with a neck that requires no tools for removal for cleaning.

What are the Limitations of Field Fabricated Assemblies?

Traditional Field Fabricated Gooseneck Assemblies share the same deficiencies. All suffer from a lack of a back-draft damper unless they use an inline butterfly damper which in a vertical orientation adds a tremendous amount of static pressure. With dryers an inline damper is against the International Mechanical Code (IMC). Alternatively, you can use a side wall cap which looks awkward. The several components that make up a field fabricated assembly all must be fastened together which adds penetrative fasteners which is also not allowed in dryer assemblies per the IMC. The many joints created in the field fabricated assembly all must be sealed from weather intrusion and is always a weather dependent process. Caulks and mastics have a limited life span and will need to be reapplied long before the roof needs to be redone, but long after your HVAC warranty has expired. Exposed galvanized duct is unprotected and will rust and deteriorate over time. Architectural details that specify insulation or adhesive weatherproofing jackets are expensive, extraordinarily time consuming, weather dependent and difficult to make look workmen like. Finally, they all require destructive methods to remove the gooseneck vents for cleaning and service of the equipment.

RoofGoose Vent Terminations

Typical Gooseneck Field Assembly

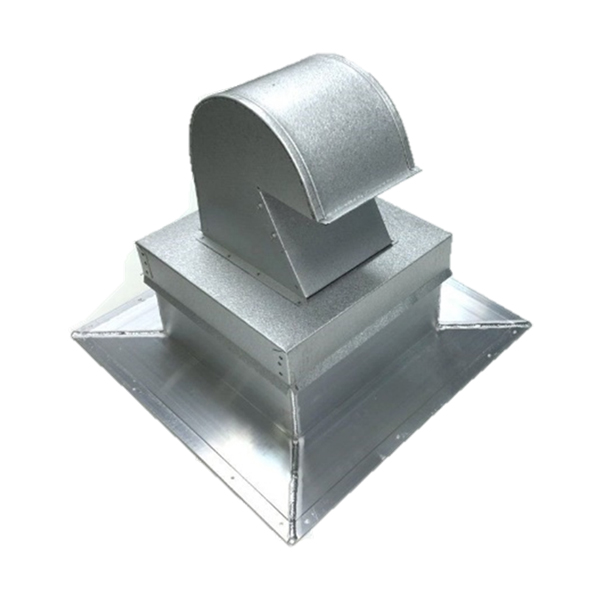

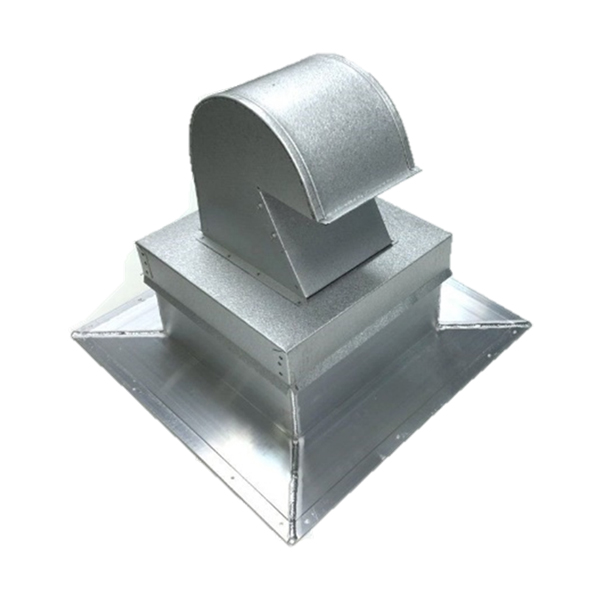

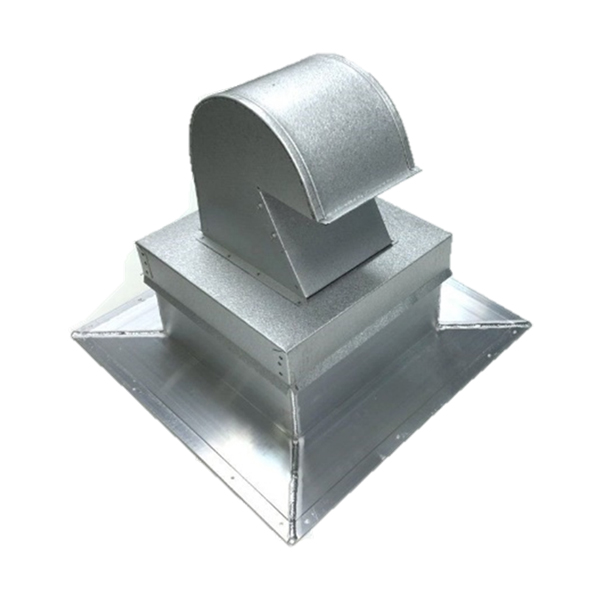

Rectangular Gooseneck On Roof Curb

Typical 90 W/ Side Wall Vent

Weather Proof:

YES

NO

NO

NO

Rust Proof:

YES

NO

NO

NO

Insulated Option:

YES

NO

YES

NO

Backdraft Damper:

YES

DON’T BET ON IT

YES

YES

Penetrative Fasteners Required:

NO

YES

YES

YES

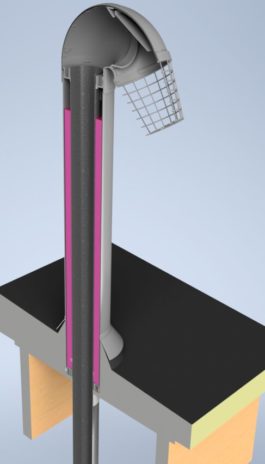

Removable Screen:

YES

NO

NO

NO

Bird Guard For Dryers:

YES

NO

NO

NO

Tool less Removal for Cleaning:

YES

NO

NO

NO

Counter Flashing Provided:

YES

NO

NO

NO

Clean Appearance:

YES

NO

NO

NO

5 Minutes or Less!

30 Min. to 1hr and 45 min. *WEATHER DEPENDENT*

3hr 30 Min. to 4hr *WEATHER DEPENDENT*

30 Min. to 1hr and 45 min. *WEATHER DEPENDENT*

RoofGoose Vent Terminations

- Weather Proof: Yes

- Rust Proof: Yes

- Insulated Option: Yes

- Backdraft Damper: Yes

- Penetrative Fasteners Required: No

- Removable Screen: Yes

- Bird Guard For Dryers: Yes

- Tool less Removal for Cleaning: Yes

- Counter Flashing Provided: Yes

- Clean Appearance: Yes

- Near Zero Static Pressure: Yes

(Click Here to See) - Install Time: 5 Minutes or Less!

Typical Goosneck Field Assembly

- Weather Proof: NO

- Rust Proof: NO

- Insulated Option: NO

- Backdraft Damper: DON’T BET ON IT

- Penetrative Fasteners Required: Yes

- Removable Screen: NO

- Bird Guard For Dryers: NO

- Tool less Removal for Cleaning: NO

- Counter Flashing Provided: NO

- Clean Appearance: NO

- Near Zero Static Pressure: NO

- Install Time: 30 Minutes to 1hr and 45 minutes weather dependent

Rectangular Gooseneck On Roof Curb

- Weather Proof: NO

- Rust Proof: NO

- Insulated Option: YES

- Backdraft Damper: YES

- Penetrative Fasteners Required: Yes

- Removable Screen: NO

- Bird Guard For Dryers: NO

- Tool less Removal for Cleaning: NO

- Counter Flashing Provided: NO

- Clean Appearance: NO

- Near Zero Static Pressure: NO

- Install Time: 3 Hrs 30 Minutes to 4hr weather dependent

Typical 90 W/ Side Wall Vent

- Weather Proof: NO

- Rust Proof: NO

- Insulated Option: NO

- Backdraft Damper: YES

- Penetrative Fasteners Required: Yes

- Removable Screen: NO

- Bird Guard For Dryers: NO

- Tool less Removal for Cleaning: NO

- Counter Flashing Provided: NO

- Clean Appearance: NO

- Near Zero Static Pressure: NO

- Install Time: 30 Minutes to 1hr and 45 minutes weather dependent